Lloyd Fox at his Solidworks CAD.

Lloyd Fox at his Solidworks CAD.

The starting point for each and every gun we make is on the CAD, the Computer Aided Design system. On this computer we keep a live model of every gun we produce, any alterations to the machinings and parts we require are updated here on an ongoing basis, this way, every different size action produced always incorporates these latest changes. This system is run and kept current by Lloyd Fox, a young, enthusiastic designer with a passion for both guns and fieldsports. It is Lloyds job to keep the gun workshop filled with actions and parts, his job also to keep the gunmakers happy with the quality of the parts he delivers, this, I can assure you, is no easy task, the gunmakers being notoriously grumpy and demanding about these items!

From the CAD drawings the components are then individually directed to the various machines we use for their manufacture. We primarily use 4 types of machines, CNC milling, Wire Erosion, Die Sink EDM and surface grinding. Some parts use one machine and others all four. There is a total of between 220 and 260 hours machining, both manned and unmanned on a full set of parts for our guns and rifles, a considerable amount of time perhaps, but when you take into account there are 90 or so parts perhaps not. We do not, actually never have, batch produced our actions. We could with no doubt produce them much more cost efficiently in batches, but being a bespoke gun business it has always seemed preferable to have control of the action sizes from the very start and I have no desire to stock 100's of different size, perhaps obsolete, action bodies.

So armed with a set of parts from the engineering shop, our next stop will be the barrel filers bench where we will see the barrels made and continue the process of making a best gun.

Martin McKee arrived last year with the new Sodick Wire Cut EDM machine which we use alongside a Charmilles wire cut.

Martin McKee arrived last year with the new Sodick Wire Cut EDM machine which we use alongside a Charmilles wire cut.

Andy Hudson on his CNC Mikron milling machine. Andy has been working on the gun parts since we started with the .410 droplocks in 1990.

Andy Hudson on his CNC Mikron milling machine. Andy has been working on the gun parts since we started with the .410 droplocks in 1990.

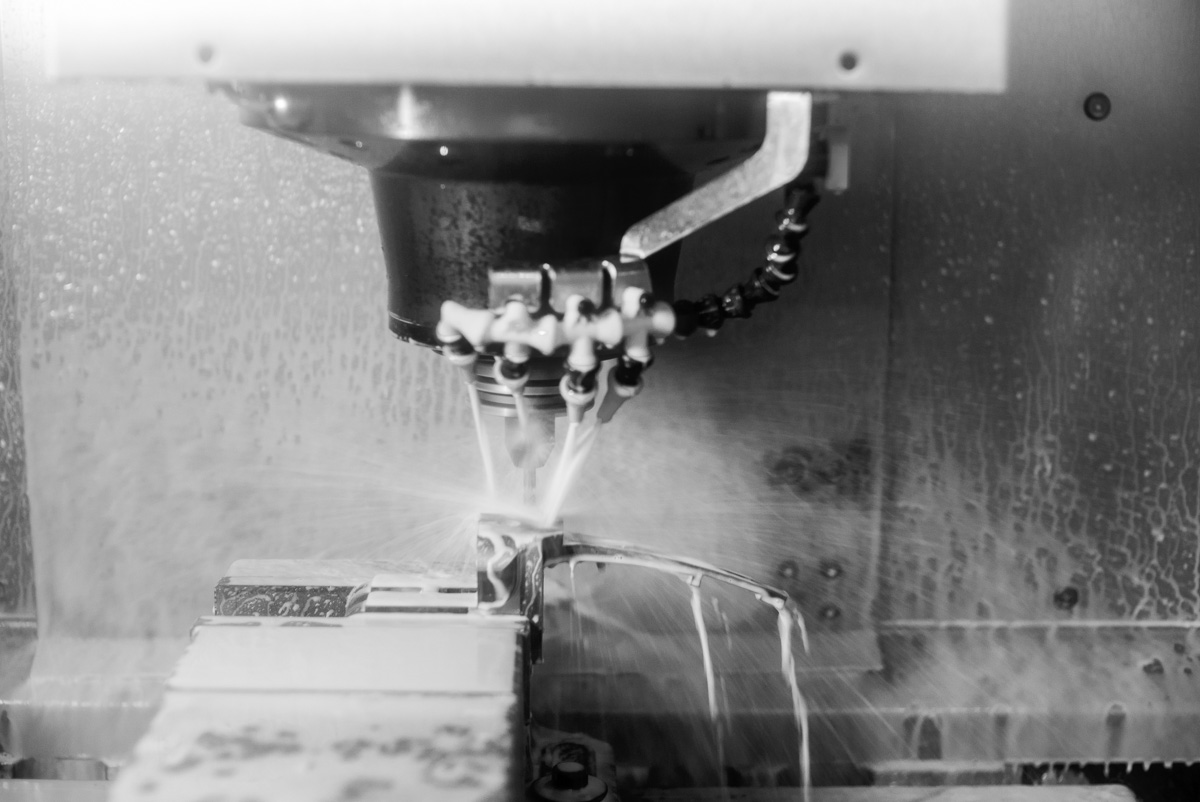

Mikron CNC Mill working on a double rifle action.

Mikron CNC Mill working on a double rifle action.

Charmilles Die Sink EDM machine which is run by Ian Ball.

Charmilles Die Sink EDM machine which is run by Ian Ball.

Paul Richards has been the Quality manager at Westley Engineering for 15 years, seen here inspecting an action on the CMM. The company holds ISO 9001, ISO/TS 16949 and we are currently renewing our Aerospace quality standard AS 9100.

Paul Richards has been the Quality manager at Westley Engineering for 15 years, seen here inspecting an action on the CMM. The company holds ISO 9001, ISO/TS 16949 and we are currently renewing our Aerospace quality standard AS 9100.

Enquire

Enquire

Vance Daigle on March 17, 2015 at 12:48 pm

WOW!!!!!!

In Christ

Vance,

Peter Martinsson on March 17, 2015 at 2:10 pm

A big thank you mr Clode for creating this fantastic blog the guns and rifles i've seen here is absolutely breathtaking.

One thing i wonder is have you ever consider making your own Mauser actions.

Best regards

Peter

Simon Clode on March 17, 2015 at 2:27 pm

Thank you!

There are too many people making the Mauser action now, some have put their own 'take' on the action thus 'making it better' - "In their opinion" and others have tried to remain faithful to the original design. It is quite a big task and project to set up and make the actions and no English gunmaker ever worried about using the Mauser action and I don't actually worry about choosing the best I can find on which to build our rifles.

I think the answer is yes, I have considered it but I don't believe the demand for huge quantity is out there for me to warrant making my own. We can watch Rigby for a year or so and find out!

Neill Clark on March 17, 2015 at 7:58 pm

As a mechanical engineer I really enjoy this thread, though machine tools have come on a bit since I used to operate them!

I think you are right about the Mauser action, there are plenty of derivatives on the mass produced market. What I can't understand with Rigby is how/why they can market their big game rifles about £4k cheaper than Mauser sell their own factory made Model 98's.

Simon Clode on March 17, 2015 at 8:40 pm

I don't get the Rigby master plan myself so I'm afraid I cannot help with an answer. I have no doubt the German owners do have a plan though, be it right or wrong remains to be seen! Perhaps they have a selection of models in the bolt rifles. I know they have a stocker working on stocking a rifle by hand at the shows and hand stocking certainly doesn't compute in the price I saw of about $10,000.

jim scott on March 18, 2015 at 4:19 pm

here we og again boys,another attack on rigby by non rigby loving INFIDELS,only bcz rigby make best guns only

Simon Clode on March 18, 2015 at 9:22 pm

I don't think it was an attack, I am also sure most gun admirers like Rigby, it is just a perfectly sensible question. Perhaps a question you, being an obvious admirer of Rigby, can enlighten us with an informative answer which will then go a long way to help people understand how and why they can offer the rifle cheaper than Mauser themselves?

Simon

Neill Clark on March 19, 2015 at 10:33 am

Definitely not an attack. I got my shotgun from them when they were still Roberts and Son, and sent Marc Newton my congratulations when it was announced that the Rigby name was back where it belongs. As Simon has said, my question was just that, a question!

Woody Cotterill on March 19, 2015 at 7:46 am

Dear Simon

Fascinating insights, thank you. Do you also machine rifle barrels entirely in house with this process?

There is no mention of the metallurgy, and how advances through the past century have influenced bespoke guns. Arguably, some of the parts could be machined lighter with the tougher steel alloys? or does the heat treating play an important role later in the production.

I have read elsewhere about what is akin to the alchemy of case-hardening (in the superb book by Vic Venters 'Gun Craft'). And this process has also been modernized.

many thanks for all these posts, my favourite blog

kind regards

Woody

Simon Clode on March 19, 2015 at 10:22 am

We do not make our own rifle barrels in house, our volumes and the spread of calibre's we make dictate that.

The case Colour hardening does dictate the steel used in the making of the guns, certainly the action body. In that respect little has changed and as we case colour every gun we make we use the same steel. We have introduced some modern steels into the working and 'unseen' parts of the guns and rifles. We are not usually looking for lightness of parts, more for durability, strength and wear issues.

Case colour hardening is a 'black art' and I hope to be covering this later on in the blog.

Thanks for your kind comments!

James de Penning on March 20, 2015 at 3:49 am

Do you receive the rifle barrels rifled or smooth?

Thanks.

James.

Simon Clode on March 20, 2015 at 7:42 am

We receive the barrels rifled in both instances, single or chopper lump for the two types of rifles we make. The rifle barrels look similar to the shotgun barrels illustrated here but more contour.

Simon