Once the checkering has been laid out and cut, the gun is delivered to the workshop of Julian Fanthome, who applies the final oil finish.

Julian's work gives the guns their flawless, glossy, oil finish. He is also tasked with running-through the checker and ensuring that every line and border is perfect, free from over-runs and clean.

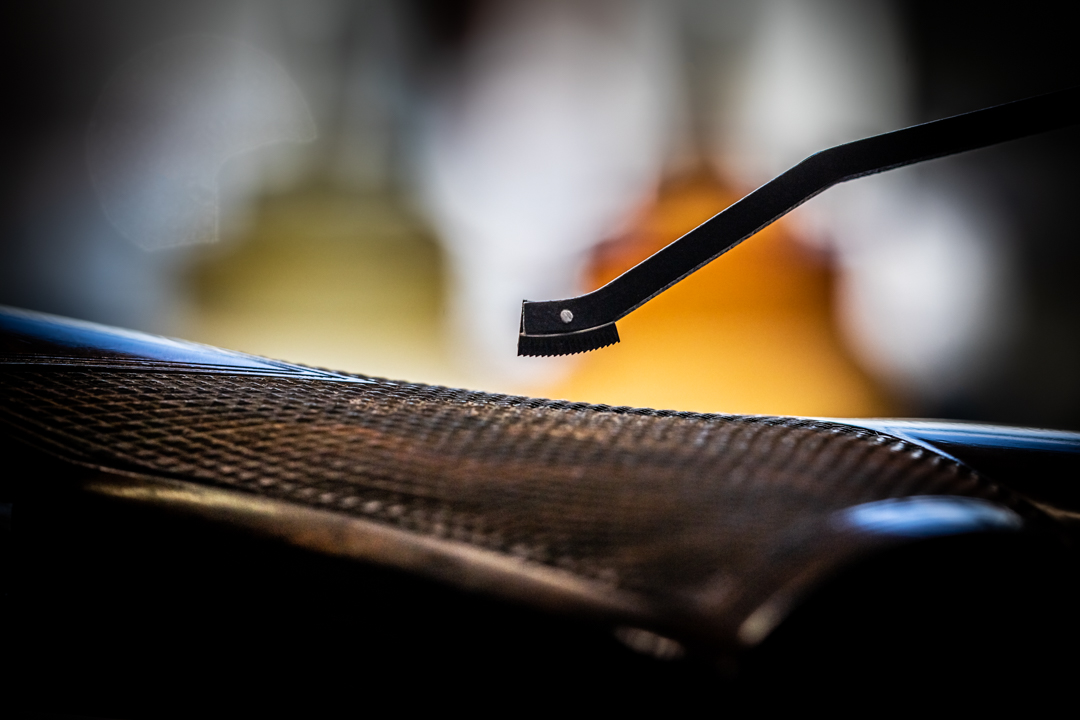

The tool he uses is a rudimentary one, consisting of a wooden handle, a steel shaft and a hardened cutting-head. The work requires intense concentration, as any slip or mis-step will result in broken line, an over-run or a broken or imperfect diamond.

The task of the checkering specialist is to lay out, then cut into the walnut, a pattern of perfectly even, sharp diamonds, which provide the grip necessary to hold the rifle or shotgun securely between the hands.

These checkering panels must be maintained and enhanced in the final stages of stock finishing to achieve that perfection of appearance demanded of a new best gun.

Precision is the name of the game and Jules is experienced in positioning himself perfectly so as to be able to apply the right direction and pressure to follow the lines and to maintain the right depth, without deviation.

The tool, which is commercially produced, looks very simple but quality is of the imperative. Heads which are not precisely cut or which are insufficiently sharp or hard produce horrible results.

Jules refines the checkering and finishes the stocks at a large window in his workshop in the Westley Richards factory, relying on natural light to provide the clear vision needed to do work of this intricate nature.

Using traditional skills, patience and this very simple looking tool, Jules applies one of the very last processes in any gun or rifle build, so the pressure to do it faultlessly is enormous.

Imagine being given a rifle that is days away from completion and may have cost the customer over a hundred and fifty thousand pounds. Then, being handed this rustic wood and steel cutting tool and told to follow those tiny, perfect, checker panels cut into the precious walnut stock. Ultimately, the final responsibility for the appearance of all that hard work falls to Jules and this tool.

Like many of the trades connected with building best guns and rifles, checkering is still done the same way it was a century ago, using simple tools like this.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.

Enquire

Enquire

Charles Faron on August 3, 2024 at 1:56 am

I'd like to purchase a copy of In Pursuit of The Best Gun 1812-2012 - 2nd Edition. USD

Rachel-Elizabeth on August 6, 2024 at 5:22 pm

Please find link below to purchase our Bicentennial History Book:

https://www.westleyrichards.com/us/in-pursuit-of-the-best-gun-1812-2012-2nd-edition