A Westley Richards gun, especially a droplock, is aesthetically quite different, with curves in most of the right places: full ball fences; broad, rounded shoulders behind them; a wide top-lever that steps gracefully down to its thumb piece; and a scalloped, scroll-back action without pin holes to scar its sides or the engraving. The action walls are also slightly rounded on each side where they meet the detachable cover plate.

Examine, for example, an early Gold Name hand-detachable model which, for embellishment, carried barely more than the Westley Richards name inlaid in gold on each side of a colour-case-hardened action. When built to best-quality standards, Gold Name droplocks cost only £5 less than best versions with standard scroll engraving (£115 versus £120 in the late 1920s). Westley Richards still builds Gold Name guns.

‘It’s gunmaking in its purest form’, says Managing Director Anthony Alborough-Tregear. ‘The actual craftsmanship must be second to none, as such a gun may reveal no flaw’.

Most new Gold Names are fixed-lock double rifles, but in 2016 Westley Richards completed a .577 3-inch rifle as a Gold Name droplock, and in 2017 another as a 20 bore shotgun – testaments to the action’s intrinsically appealing lines.

Through the 1930s, Westley Richards was renowned for its presentation-grade guns and rifles, which were especially popular with the Maharajas of India. Among them were the droplock Modèle de Luxe (‘elaborately and artistically carved and engraved with Game subjects’, per the company’s 1912 Centenary catalogue) and Modèle de Grande Luxe (‘the attainments of the artist engraver are here given the fullest scope’).

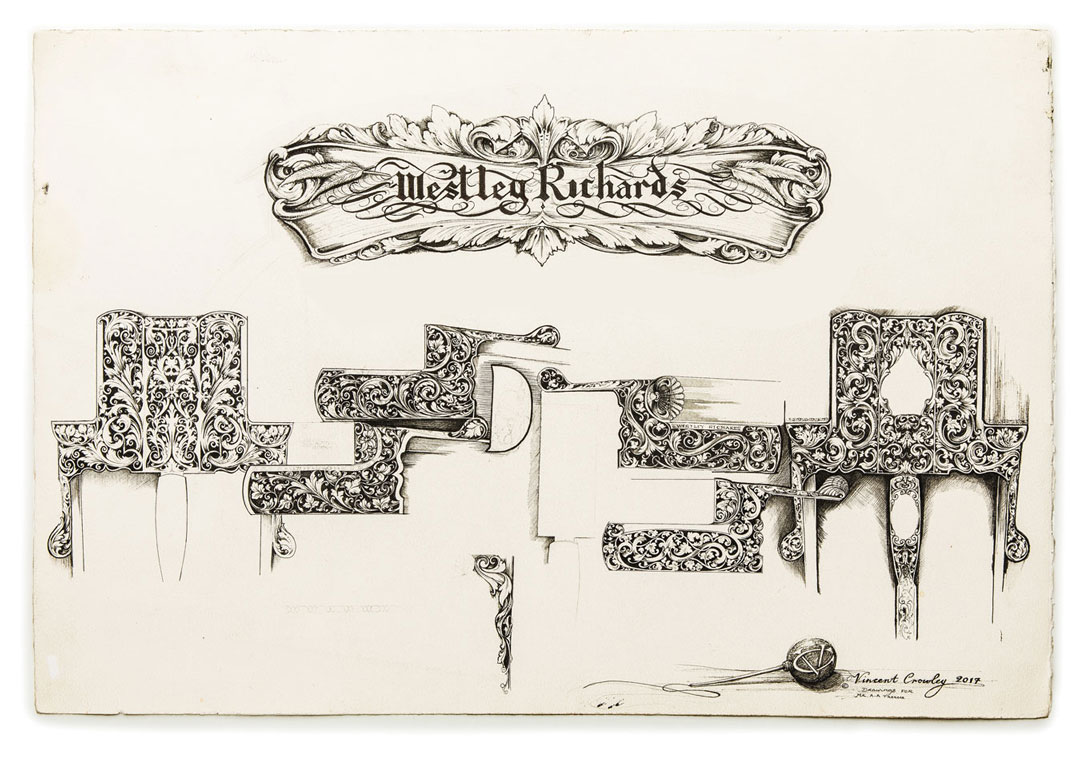

Pen-and-ink drawings by engravers are normally commissioned only for Westley Richards presentation-grade projects, such as those featuring elaborate scroll or game scenes with elaborate scroll, and art guns with deep carving and inlays of jewels and precious metals. Such a drawing is a work of art in itself. It can be expensive, but it can provide the client, the gunmaker and the engraver with a variety of choices on which to base the final design. For the 28 bore droplock here, Vince Crowley provided a range of lush scroll compositions, each subtly different, and with seashell motifs for the fences and toplever. Note Crowley’s tasteful balance between shaded and unshaded elements of scroll in his designs.

Pen-and-ink drawings by engravers are normally commissioned only for Westley Richards presentation-grade projects, such as those featuring elaborate scroll or game scenes with elaborate scroll, and art guns with deep carving and inlays of jewels and precious metals. Such a drawing is a work of art in itself. It can be expensive, but it can provide the client, the gunmaker and the engraver with a variety of choices on which to base the final design. For the 28 bore droplock here, Vince Crowley provided a range of lush scroll compositions, each subtly different, and with seashell motifs for the fences and toplever. Note Crowley’s tasteful balance between shaded and unshaded elements of scroll in his designs.In their day, Grande Luxe droplocks – with scroll engraving that spooled to infinity, carved game scenes, ‘gold incrustation’ and sometimes multi-colored enamel portraits of Indian personages – were probably the most expensive shotguns made in Britain, costing more than twice as much as best-grade sidelocks from the toniest London houses.

After the Second World War, the tradition of building presentation guns was nearly lost, not only at Westley Richards but everywhere, as extravagant orders from overseas clients vanished along with the British Empire. Following in the footsteps of his father Walter Clode, Managing Director Simon Clode began to rebuild the tradition in the 1980s by developing relationships with the most prominent American gun collectors and then building guns and rifles – with engraving to match – to their very discerning standards.

One of Clode’s most important accomplishments was developing a team of engravers that worked exclusively for Westley Richards, which meant sometimes taking chances on budding unknowns not yet sought after by the collectors.

‘We’ve been very fortunate in recent years to gain the patronage of some very forward-thinking clients whose support has allowed us to develop and nurture new engravers’, says Alborough-Tregear.

One of Westley Richards’ house engravers is Vincent Crowley (42), who was invited to join the firm 20 years ago after Clode recognised his potential. Clode paired him with the hyper-talented Rashid El Hadi, who had come to the firm just a few years earlier. ‘Rash’ took him on as an apprentice. ‘He was a great tutor to me’, said Crowley, ‘and also Peter Spode another Westley Richards engraver who was a constant help. As a young engraver, I couldn’t have wished for a better beginning’.

Clode, who died in 2016, himself took an active role in improving the engraving on Westley Richards guns. ‘Simon was very artistic’, Alborough-Tregear told me. ‘He had a great eye for layout and detail’.Crowley recalled that Clode always encouraged him to push his boundaries and to be creative, ‘but he also stressed elements of engraving that should be respectful to the company’s history’.

The new scroll-engraved 28 bore droplock featured here is a perfect example of Crowley’s innovation combined with his respect for tradition and, moreover, it shows us how well-executed designs can enhance and flatter the lines of a gun.

‘The basic boxlock shape presents a design challenge to any engraver’, explained Crowley from his home workshop in Worcestershire. ‘A sidelock has a sweeping curve at the rear of the plates that serves as a starting point for a flowing pattern’.

But on a droplock there are straight lines to overcome, to complement and to render mellow to the eye. ‘Droplocks are rounder than standard boxlocks, but they’re still more angular than sidelocks’, Crowley noted. ‘Properly designed engraving helps soften that angularity’.

For Crowley, design begins by first considering the gun in toto. ‘For me, it’s critical to see a droplock complete, with its stock, as opposed to steel components alone that need engraving’, he said. ‘With a droplock, an engraver needs to tackle the design with ingenuity’.

For Crowley, ingenuity sometimes begins with bringing the marbled figure of the walnut stock into his design: ‘On some droplock shotguns, I’ve used the figure of the stock where it meets the back of the action as a starting point for the main scroll. Consequently, every other scroll forms from that prominent line. This provides an uninterrupted flow to the overall aesthetic’.

The 28 bore was commissioned with lush, full-scroll engraving and, because of its complexity, Alborough-Tregear asked Crowley to submit several designs. ‘My pen-and-ink drawing showed a few different options so that Trigger and the client could get a good idea of the choices and then pick between subtle changes in the scroll’.

Crowley took his inspiration for the 28 bore from a set of 19th-century French engraving patterns. ‘Simon had discovered them years ago, and we often thumbed through them in our discussions about engraving’, said Crowley. ‘This was my first opportunity to apply their influence’.

Crowley showed a couple of his engraving samples in butterfly form, laid out continuously as if on a single surface. ‘As a result’, he explained, ‘when you rotate the finished gun, the pattern continues and flows over three separate surfaces – a useful technique to soften the droplock’s shape’. Carved seashell motifs are a favourite of Crowley’s, and on the fences here they add a dramatic counterpoint to the scroll. ‘I really like to make the fences a stand-out feature on these smaller actions’, he said.

Because the 28 bore fences weren’t large enough to incorporate the full depth of the scallop-shell shape, Crowley continued the flutes up the breech-ends of the barrels ‘so that when the gun is open, the design still works visually on the barrels as well as on the fences’. Crowley also integrated smaller seashell motifs atop the doll’s head, notably, and underneath, on the trigger guard. He also carved the thumb piece on the opening lever as a beautifully symmetrical shell. ‘This was an obvious choice because, like the fences, the thumb piece itself is a perfect shell-like shape. I engraved it simply, just as I drew it. It’s very rewarding when the simplest of designs turns out this well’.

Crowley’s finished 28 bore is a masterpiece of modern Westley Richards engraving. It is of exhibition quality, yet not so rarified that it couldn’t be taken afield – which is, after all, the purpose of a gun. The scrolls, with their flowing foliate elements, combined with the shell motifs create an almost organic aesthetic, as if sprung from nature and not from a gunmaker’s vice. Crowley’s composition enhances the lines of the gun everywhere, and while it draws from historical continental influences, its appearance is contemporary – timeless.

‘I hope the finished gun pleases its owner’, said Crowley. ‘It’s a Westley Richards I would love to own and use’. As would anyone.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.

Enquire

Enquire