With the barrelled action 'in-the-white' prepared and assembled, the measurements and surfaces to be inlet into the stock will already have taken their basic form.

The necessary internal shapes are cut to bed the action, top strap, magazine box and barrel precisely into the selected walnut blank.

With the metalwork securely bedded, Jordan Hermant, who has been stocking rifles at Westley Richards for a decade, begins to cut the rough blank into the shape of a stock.

To do so, he uses a variety of tools, like a band saw, draw knife, milling machine, plane and chisel. He starts with the central section of the rifle, either side of the magazine box. As he gets the shape and proportions here right, so the line to develop the forward and backward shapes becomes evident.

Every rifle is different, and while the customer provides drop, cast and length measurements, Jordan uses his experience and knowledge of Westley Richards shapes for each section of the stock to fashion these appropriately for each rifle. Adjustments are considered, such as the customer's hand size and the scale and calibre of the rifle in order to achieve overall harmony.

Jordan keeps the metal-work fixed in place while working the wood, as it provides strength and a visual reference as to scale and proportion. The company style for stocking magazine rifles is passed down through generations of stockers; ensuring that a Westley Richards rifle looks like no other, with all the small details remaining true to form.

Jordan will shape the stock to its final proportions, including fitting a forend cap in ebony, if required. He also shapes and fits whatever butt-finish is specified, such as heel and toe plates, rubber anti-recoil pad, or chequer-panel outline.

A standard Mauser-action magazine rifle typically requires one hundred hours in the stocking shop. Our variations include the .425 Westley Richards with the square box magazine and guide clips and the two take down rifles we offer; with either bayonet or screw-thread systems.

These take longer to stock, with a take-down rifle often requiring an additional thirty hours of work to cut the forward section, fit steel plates and inlet the release-catch. In some cases, that requirement might extend to as many as fifty extra hours.

The side-clips of the .425, which guide the rounds into the breech, require careful hand-cutting of the channels into which they fit, for which Jordan has fashioned a special dog-leg chisel.

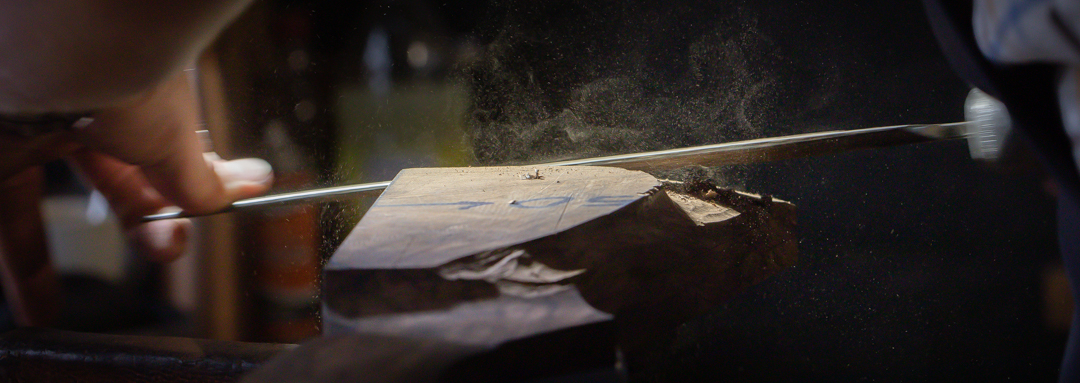

Before a rifle leaves Jordan's bench, he uses smoke-black, chisels and abrasive paper to achieve the final, perfect, hand-bedding of steel into walnut. The wood in question is, of course, walnut and the vast majority of that comes from Turkey today. In the period leading up to the Second World War, French walnut was the preference of the British gun trade. These days, French walnut supplies are essentially exhausted.

Some blanks are easier and more pleasant to work than others. As a natural material, every blank is an individual and its qualities vary from one to another.

Factors affecting the structure of the wood include the age of the tree, the climate in which it grew, the care with which it was felled and cut into blanks and the ageing process.

In his ten years at Westley Richards, Jordan has only ever encountered one blank which had to be scrapped mid-way into a job. It cracked across the mid-section of the action.

On occasion, he may encounter a shake, hole or knot in the butt section but these can be plugged invisibly with no detriment to the finished stock.

With the stock shape finalised and every steel part that comes into contact with the wood perfectly fitted, including grip-cap, butt-pad or plate, cheek-piece, take-down mechanism and catch (if applicable), Jordan will paper it to a finish of 600 grit and apply one coat of oil.

With that, the stocker's work is done, and he moves on to the next job.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.

Enquire

Enquire