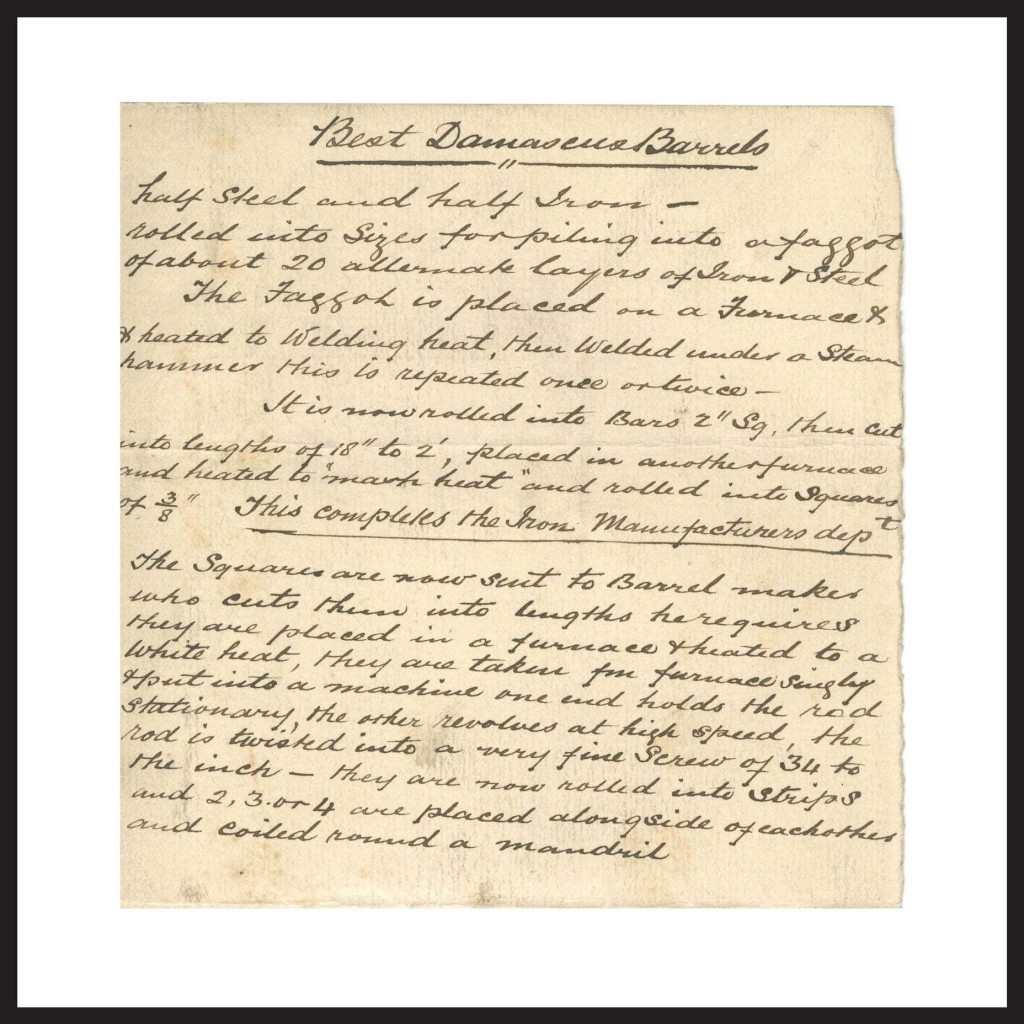

It is now rolled into bars 2" square, these cut into lengths of 18" to 2', placed in another furnace and heated to "mark heat" and rolled into squares of 3/8". This Completes the process from Manufacturers dept.

The squares are now sent to Barrel maker who cuts them into lengths he requires they are placed in a furnace & heated to a white heat, they are taken from furnace singly and put into a machine one end holds the rod stationary, the other revolves at high speed, the rod is twisted into a very fine screw of 34 to the inch- they are now rolled into strips and 2, 3 or 4 are placed alongside of each other and coiled around a mandril"

Top. A sample of damascus barrel showing the construction.

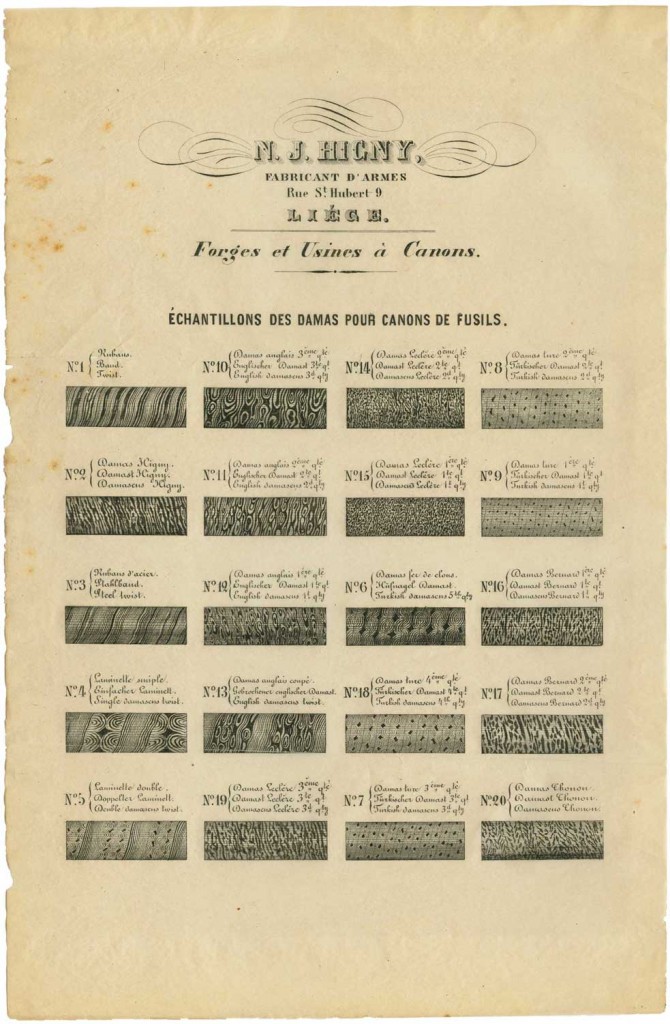

Bottom. A Liege barrel makers pattern sheet showing damascus options.

There has always been a great deal of interest and admiration for damascus barrels and the skill of making them. Today gunmakers such as W.W. Greener use old damascus blanks and build new guns to order with them. James Purdey have even introduced a fully damascus gun! These small items from our archive demonstrate, I hope, the process of making the barrels and the skill that was involved. The better the skill, the better the pattern in the damascus!

Enquire

Enquire

Keith on July 8, 2016 at 1:10 am

could there ever have been a more beautiful way to display quality control to clients?

A fine Damascus pattern, showing that both the iron and steel (in the days when neither were "fluid") had been well forged in order to thoroughly disperse slag inclusions and to align them into a "grain"

and by that forging to show that neither the steel nor the iron was subject to "shortness"

Then in twisting the strips and forge welding them into tubes, the barrel makers were showing to customers who understood implicitly, even if they couldn't express it mathematically until the final years of the nineteenth century

that the inclusions and weaknesses in the metal had been orientated so that they were subjected to the least destructive of the stresses during firing...

There's more to write on this ;-)

Herbert Wessel on March 13, 2019 at 7:13 pm

Dear aficionado, I use a WR Boxlock from 1882 in 20/65 both for Hunting, Skeet and „Jagdparcour“ clay shooting (hunting is the translation of Jagd). It,s weight is sligtly under five pounds . For hunting I use hull catrigdes for clay shooting Rottweil Fasan with felt plug. Each ca 4/5 oz lead. I am very satified with my shooting with my little WR. The Gun shows 137 years of use, there is nothing than pure steel and iron with the original barrels, but it works very well.