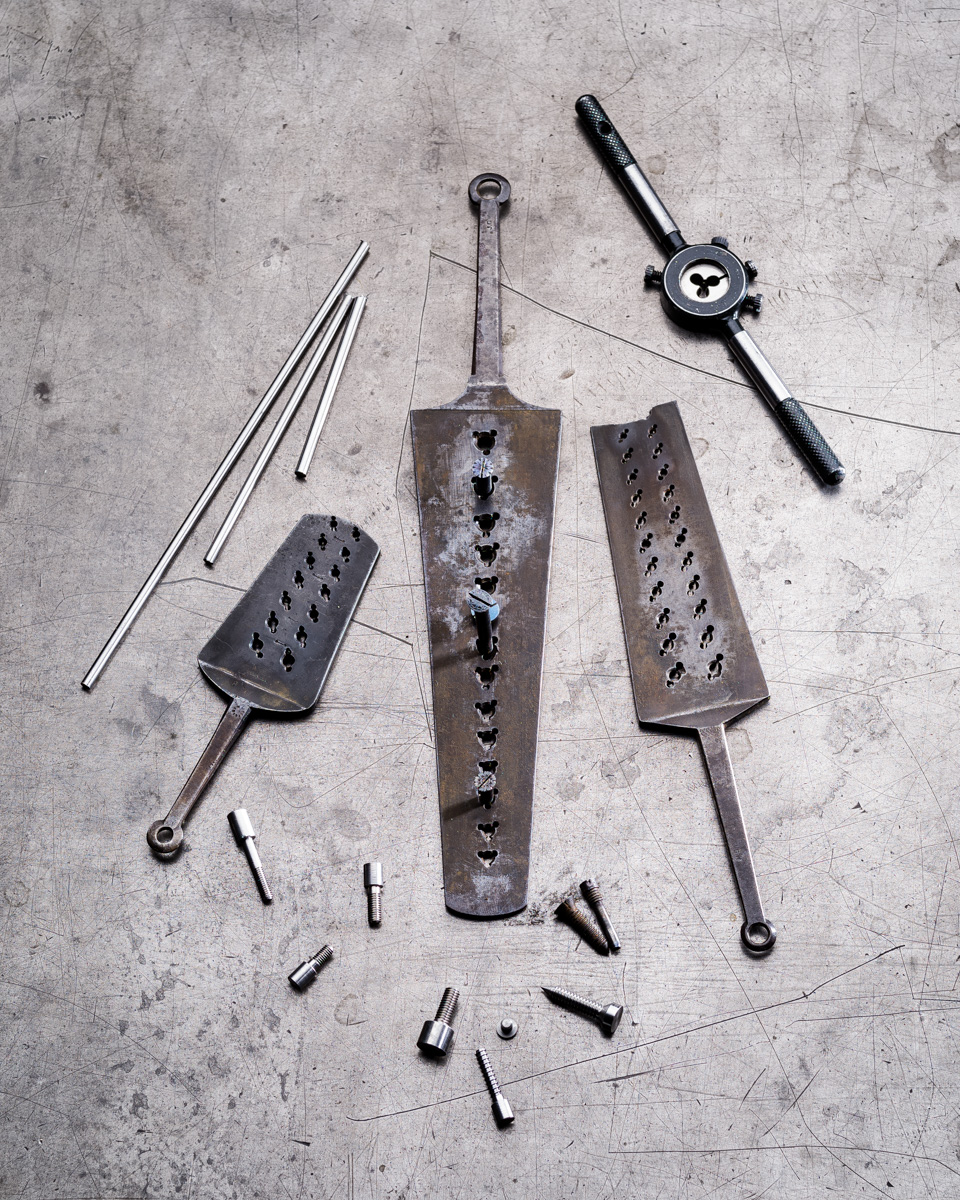

The procedure for cutting the threads was much the same as with modern die cutters. A piece of silver steel was turned to the correct size and run through the chosen slot in the screw plate. The increments in size were small and many on these screw plates fall between the now standard BA sizes.

To make a corresponding tap for the female thread for the pin made another largest diameter piece of silver steel is run through the die and then small slots are ground vertically up the cut thread, the whole then hardened and tempered to cut the female thread size.

Enquire

Enquire