For more than 100 years it was the only firearm manufactured in such a way and most likely the only example known.

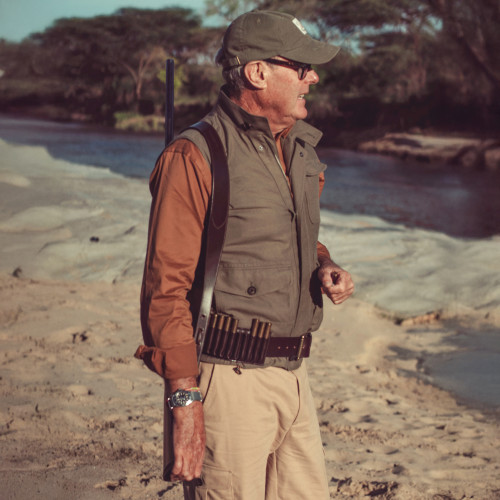

When the American boy grew up he tried to buy the Holland & Holland rifle but it was not for sale. Not to be defeated, in 2015 when he reached his fifties, he decided to commission a rifle to eclipse it. As a patron of Westley Richards for 30 years, when it came to creating the reality of this long-held dream it was to the Birmingham-based gunmaker he turned.

A triumph of creativity and technical ability, the magnificent ‘First Spear’ double rifle made by Westley Richards demonstrates true craftsmanship in action.

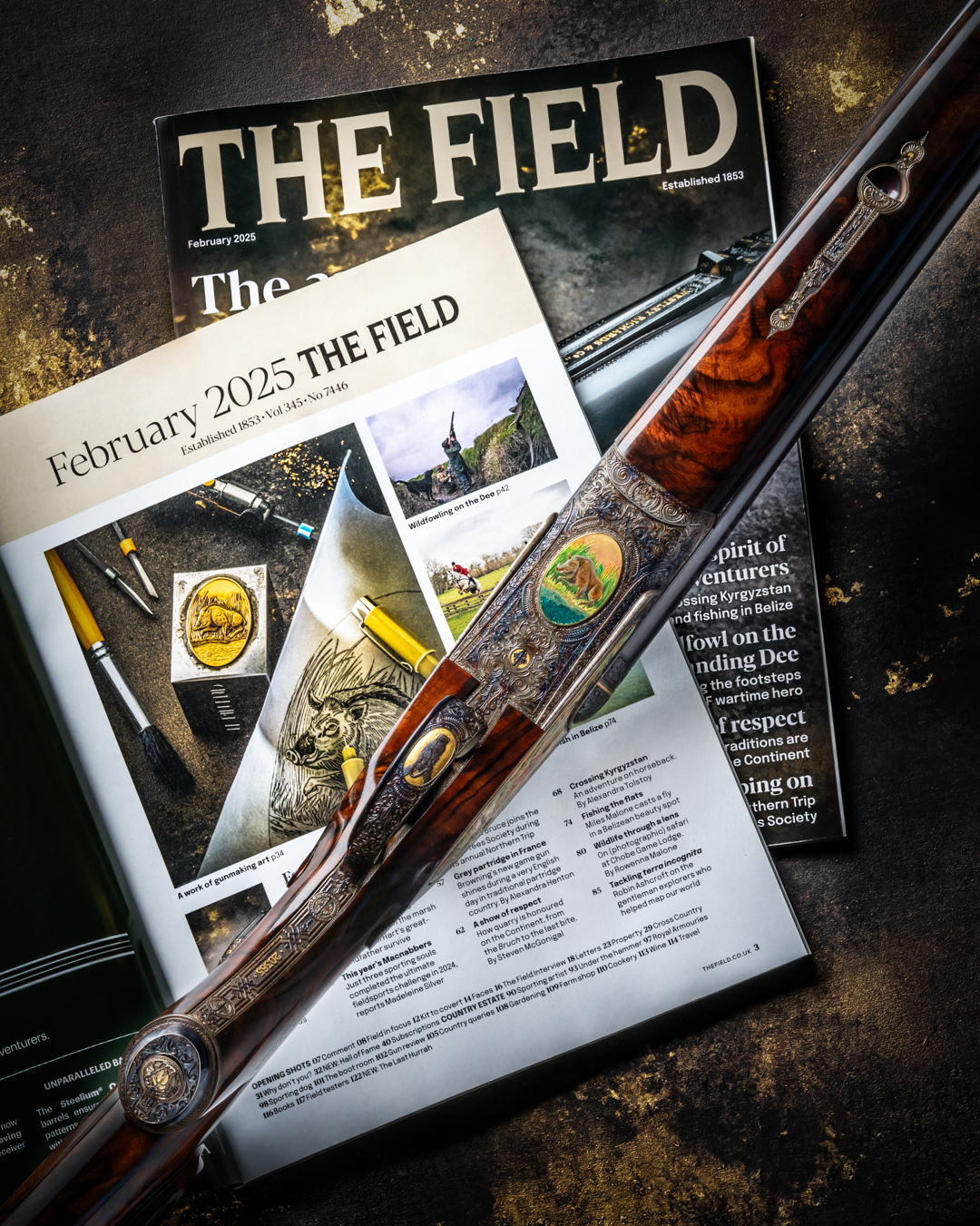

A triumph of creativity and technical ability, the magnificent ‘First Spear’ double rifle made by Westley Richards demonstrates true craftsmanship in action.This is the story of the First Spear rifle and the men and women who dedicated up to a decade of their lives to creating it. Having edited two sporting magazines and shot throughout my life, I’ve seen many rifles and shot-guns but this gun is a triumph of creativity, technical ability and craftsmanship on a scale I’ve not seen before. It has fused gunmaking and art, pushing it to the limit. The 213-year-old gunmaker believes that this is the only modern gun with this type of ornamentation in the world.

The absence of chequering on the woodwork highlights the rifle’s elegant lines.

The absence of chequering on the woodwork highlights the rifle’s elegant lines.When I see the First Spear in its bespoke alligator case at the factory, all I can do is stare. It is a .450/.400 sidelock double rifle with 25in barrels and weighs 10lb 101/2oz. Nothing unusual about that but what makes the rifle stand out are the elaborate enamelled sideplates, illustrating a historical pig-sticking scene: hog hunting on horseback in British India. Inspiration came from one of Westley Richards managing director Anthony Alborough-Tregear’s many hunting books, In The Days When We Went Hog-Hunting by James Moray Brown (1891). The sport was popular among cavalry officers during the 19th and early 20th centuries where the ‘first spear’ (the first man to hold up a bloodied spear) advanced to the next round of the competition, the most famous of which was the Kadir Challenge Cup (won in 1883 by Sir Robert Baden-Powell, who would go on to found the Scout Movement).

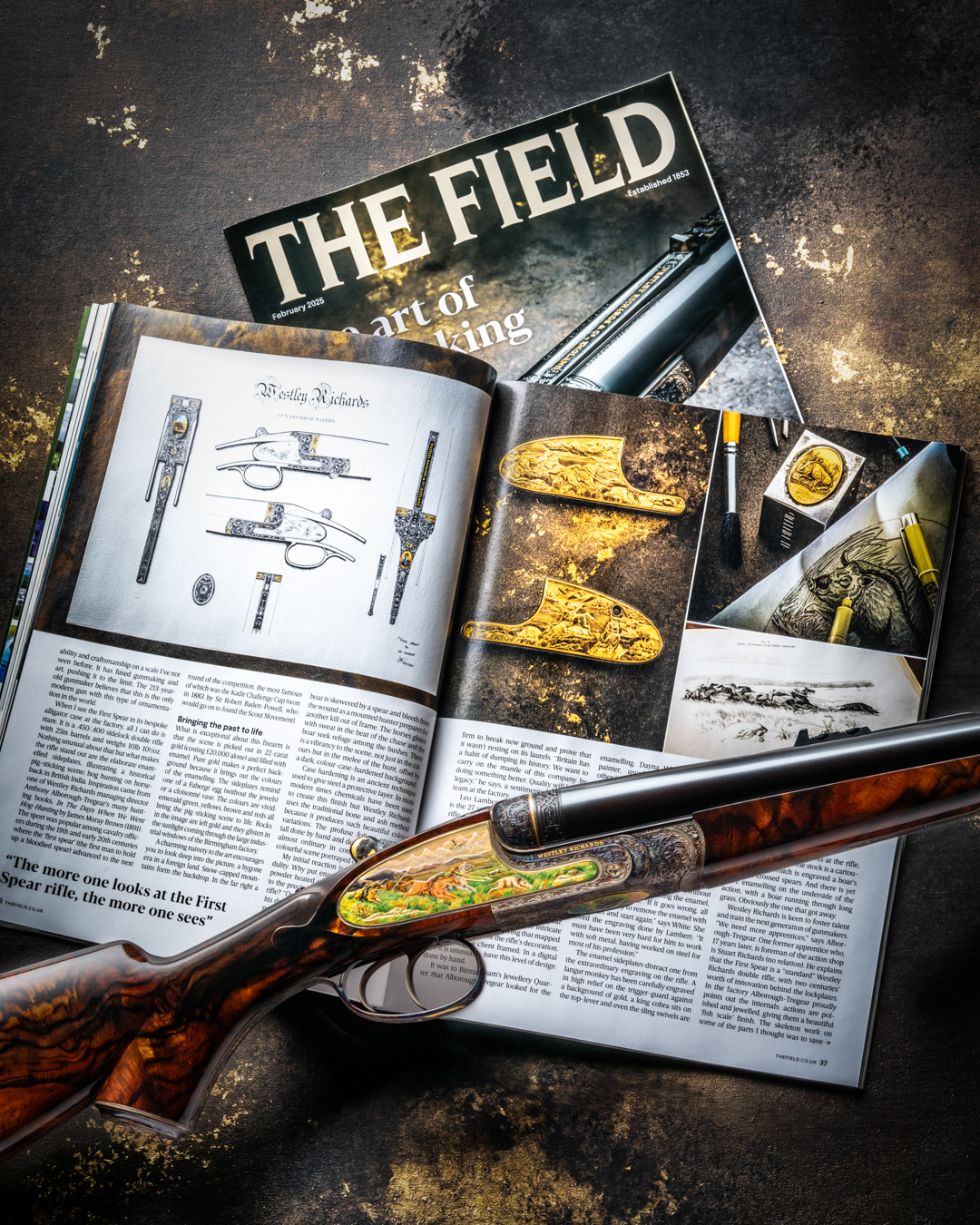

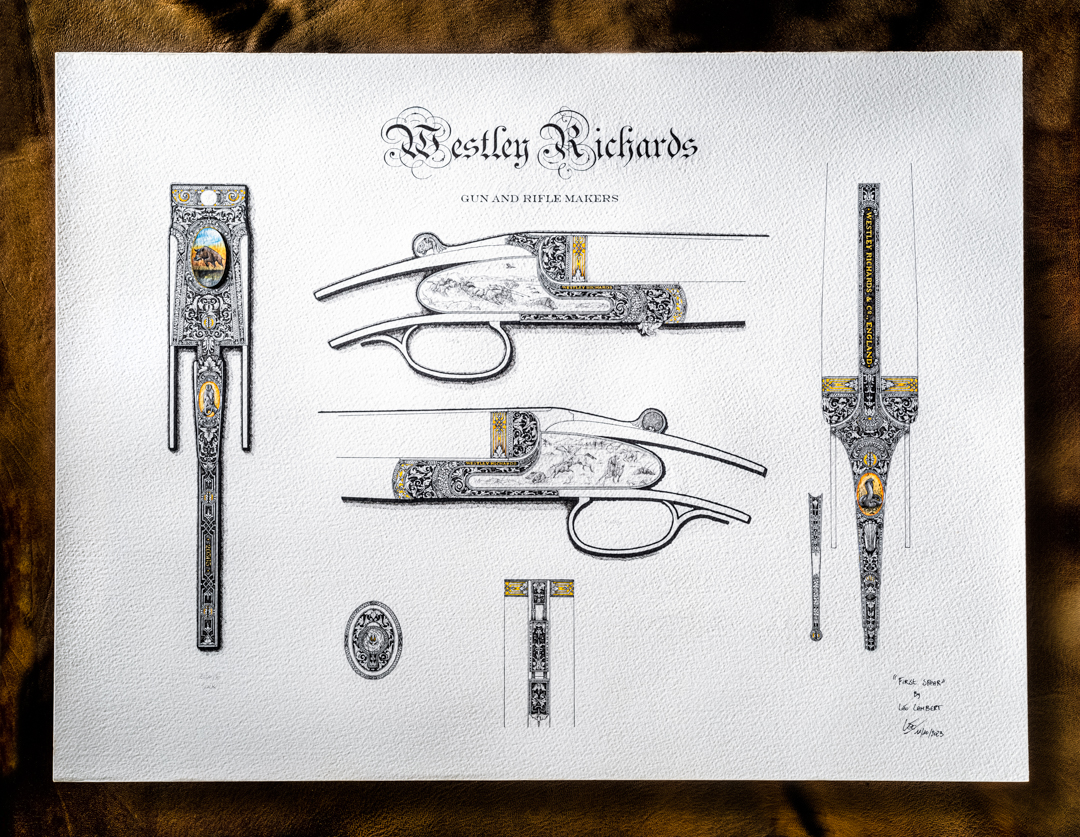

Westley Richards engraver's original artwork for the First Spear.

Westley Richards engraver's original artwork for the First Spear.What is exceptional about this firearm is that the scene is picked out in 22-carat gold (costing £20,000 alone) and filled with enamel. Pure gold makes a perfect background because it brings out the colours of the enamel. The sideplates remind one of a Fabergé egg (without the jewels) or a cloisonné vase. The colours are vivid: emerald green, yellows, brown and reds all bring the pig-sticking scene to life. Rocks in the image are left gold and they glisten in the sunlight coming through the large industrial windows of the Birmingham factory.

A charming naivety to the art encourages you to look deep into the picture, a bygone era in a foreign land. Snow-capped mountains form the backdrop. In the far right, a boar is skewered by a spear and bleeds from the wound as a mounted hunter prepares for another kill out of frame. The horses glisten with sweat in the heat of the chase and the boar seek refuge among the bushes. There is a vibrancy to the scene, not just in the colours but in the melee of the hunt, offset by a dark, colour-case-hardened background.

Case hardening is an ancient technique used to give steel a protective layer. In more modern times chemicals have been used to create this finish but Westley Richards uses the traditional bone and ash method because it produces such beautiful colour variations. The profuse foliate engraving (all done by hand and deeply picked) looks almost ordinary in comparison with the colourful scene portrayed on the sideplates.

My initial reaction is born out of incredulity. Why put enamel – effectively glass powder heated until it melts and adheres to the precious metal – on a large-calibre rifle? “Our patron asked if we could make his dream a reality. It was a challenge like no other. And I love to be challenged,” says Alborough-Tregear.

For him, this was more than just another gunmaking job. It was a chance for his firm to break new ground and prove that it wasn’t resting on its laurels. “Britain has a habit of dumping its history. We want to carry on the mantle of this company by doing something better. Quality will be our legacy,” he says, a sentiment shared by the team at the factory.

“The more one looks at the First Spear rifle, the more one sees”

“The more one looks at the First Spear rifle, the more one sees”Léo Lambert, originally from Belgium, is the 27-year-old head of engraving. “This rifle caused me a lot of frustration as I sought to solve the numerous technical problems,” he admits. For the seven years he has worked at the company it has been in the background of everything he has done. “If I wasn’t working on it, I was thinking about it,” he adds. “But I am so grateful I got the opportunity to work on this project. It took me beyond what I thought I was capable of.” Lambert was responsible for designing the engraving on the First Spear. Alborough-Tregear shows me the intricate pen and ink technical drawing that mapped out the final design of the rifle’s decoration. It will go to the client framed. In a digital age, it is unusual to have this level of design done by hand.

It was to Birmingham’s Jewellery Quarter that Alborough-Tregear looked for the enamelling. Dayna White is an enamel painter, usually making cufflinks and other jewellery. She was known to Westley Richards because she does the enamelled cartouches required on some guns but this was a whole different ball game. “At first I thought Trigger [Alborough-Tregear] was talking about decorative covers to the sideplates,” she says, “because to put enamel on a rifle that will be exposed to the elements and knocked around during use is crazy, as it can crack and chip.”

Technical challenges, such as baking the enamel and gold in an oven to 150°C without the gold warping and cracking the enamel, had to be overcome. “If it goes wrong, all you can do is try to remove the enamel with chemicals and start again,” says White. She loved the engraving done by Lambert: “It must have been very hard for him to work with soft metal, having worked on steel for most of his profession.”

The enamel sideplates distract one from the extraordinary engraving on the rifle. A langur monkey has been carefully engraved in high relief on the trigger-guard against a background of gold, a king cobra sits on the top-lever and even the sling swivels are engraved. The more one looks at the rifle, the more one sees. On the stock is a cartouche of gold on which is engraved a boar’s head and crossed spears. And there is yet more enamelling on the underside of the action, with a boar running through long grass. Obviously, the one that got away.

The underside of the action shows an enamel wild boar, while a langur monkey sits atop the trigger-guard bow.

The underside of the action shows an enamel wild boar, while a langur monkey sits atop the trigger-guard bow.Westley Richards is keen to foster talent and train the next generation of gunmakers. “We need more apprentices,” says Albor-ough-Tregear. One former apprentice who, 17 years later, is foreman of the action shop is Stuart Richards (no relation). He explains that the First Spear is a “standard” Westley Richards double rifle, with two centuries’ worth of innovation behind the lockplates. In the factory Alborough-Tregear proudly points out the internals: actions are polished and jewelled, giving them a beautiful ‘fish scale’ finish. The skeleton work on some of the parts I thought was to save weight or make the part stronger, is a reintroduced innovation because “it looks nice”, says Alborough-Tregear. Indeed the working parts of the action look like a fine Swiss watch movement. The care that goes into the presentation of parts only a gun-smith would ever see is a matter of pride for the whole team.

One of the detailed enamel game scenes, complemented by a king cobra and tiger’s head carved onto the top-lever.

One of the detailed enamel game scenes, complemented by a king cobra and tiger’s head carved onto the top-lever.V-springs still power the firing pins because they give a quicker lock time and a better feel to the trigger-pulls. Richards points out that the lock-up is the famous ‘doll’s head’ bolting system, patented around 1860 by Westley Richards. Likewise, the fore-end also uses the Deeley latch. The patent has long expired and it is used the world over on various shotguns and double rifles. Two gold rings adorn the muzzle and the foresight is a special flip-over hooded design, again a Westley Richards innovation used to protect the sight.

When the rifle is assembled I see it in full for the first time. A red SW Silver & Co recoil pad gives it a practical look and a little goldwork on the fences highlights its pedigree. Yet the First Spear will not see first blood. “Our patron insists that it will never be shot,” says Alborough-Tregear. Perhaps it’s too delicate to take into the field? “This rifle is built to be used,” Richards inter-jects. “It groups at 1.5in at 50 yards and I am a little sad it won’t see any action, but it means that it might end up in a museum and people will be looking at my work.” He bends down and shows me the pins in the sideplate, beautifully engraved and countersunk so that the torque of the pin does not crack the enamelling.

Jonathan Hay, production manager, isn’t worried that the rifle will not be used. “It’s a testament to all of us who worked on it and I am glad the patron will look after it. It will have a life beyond us,” he says. I look at the top strap and see that it extends along the grip up to the comb. “That’s not just decoration,” explains Hay, “it adds strength to the stock.” Another interesting feature: the grip is not chequered, as the client isn’t keen, which means the walnut has to be chosen for its figuring in its entirety. It’s rather lovely to see the beauty of the wood around the head of the stock.

The ‘First Spear’ rifle complete in its bespoke alligator case.

The ‘First Spear’ rifle complete in its bespoke alligator case.The rifle was already beginning to take on a life of its own. Through an American patron, the Birmingham company has created a masterpiece that combines art, craftsmanship, technology and engineering to make a high-precision hunting rifle that will still be around in a century or more. “These guns and rifles are a blank canvas on which we can show off our expertise to the world,” says Alborough-Tregear. “This is my magnum opus,” adds Lambert. “You only get a job like this once in a lifetime,” concurs White.

The American patron was moved to tears when he saw the rifle, the embodiment of his childhood dream. But was he moved to tears when he saw the bill? “It was reassuringly expensive,” confirms Alborough-Tregear. As Henry Royce of Rolls-Royce once said: “The quality remains long after the price is forgotten.”

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.

Enquire

Enquire