No firm in history has made more double rifles than Westley Richards and those they build now are designs that emerged from their own factory in the 19th century. The ‘fixed lock’ Anson & Deeley action was patented by Westley Richards employees in 1875 and the ‘hand detachable lock’, which is their signature model, was the creation of former Managing Director and celebrated ballistician Leslie B. Taylor.

The operating lever on all their double rifles and shotguns is the famous bolted 'Model C’ top-lever the firm has used since the late 19th century.

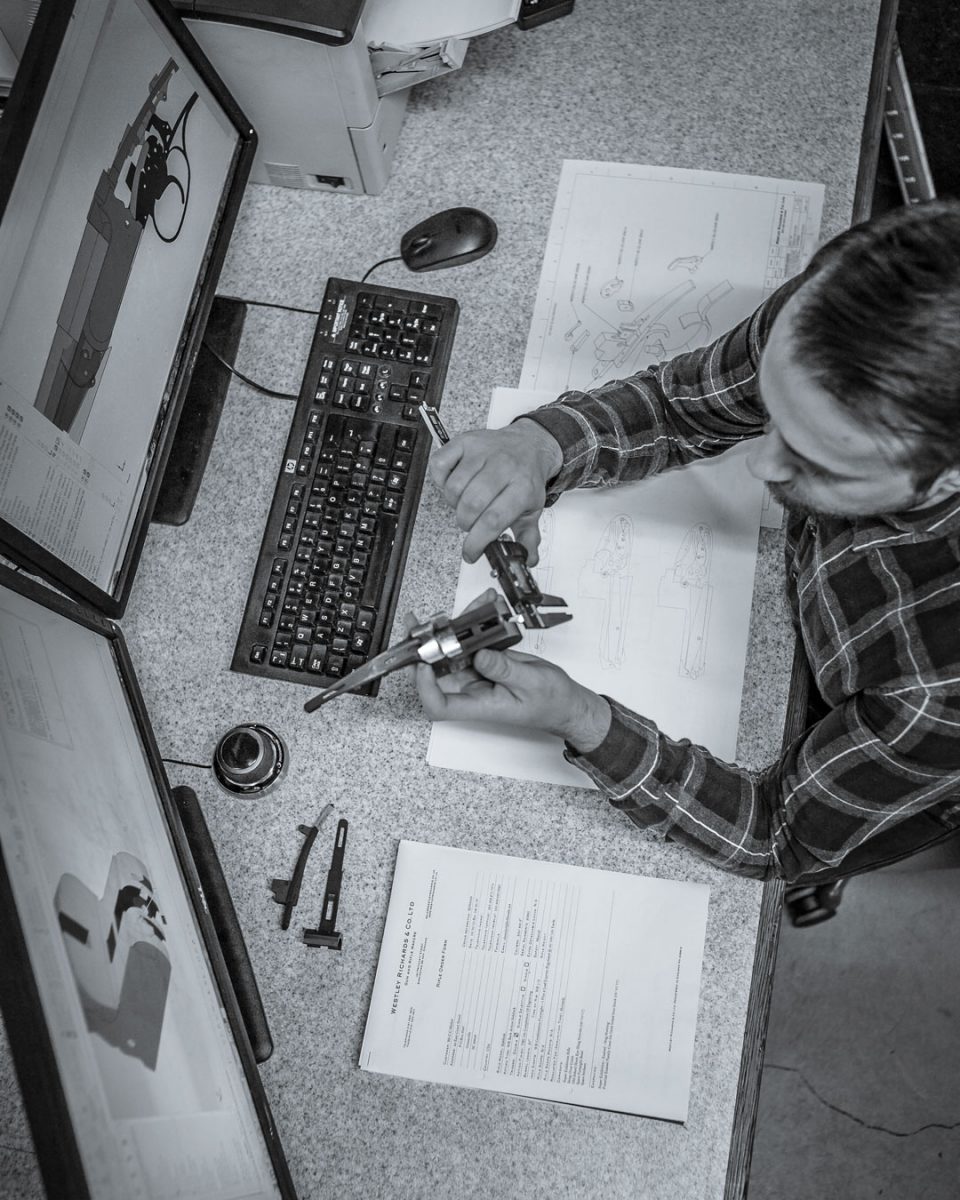

Modern gunmaking at Westley Richards is a combination of both modern and traditional gunmaking techniques. Whilst modern CNC machines manufacture many of the raw components based on CAD CAM design, traditional Bridgeport mills still assist with elements of the finer work, unique to each gun and rifle. At this point the gun has yet to absorb the finesse and feel that only a highly trained gunmaker can impart into it.

Westley Richards sporting guns and rifles have been the choice of eminent sportsmen and explorers for two centuries, from Col. Peter Hawker, through King Edward VII, to celebrated elephant hunter, Captain James Sutherland. That calibre of clientele is hard-won through constant innovation and rigorous quality control.

Close to the heart of their gun making is the city of Birmingham, home to Westley Richards since the firm was founded in 1812. Birmingham has industry in its bones and its gunmakers have inherited the dedication to their craft that only an unbroken time-line of gun making excellence provides. Above all, Westley Richards guns and rifles are embodiments of their passion for their work and their tireless quest to make the best gun that can be made.

The jointing of barrels to action has remained unchanged since Westley Richards first introduced its famous model 'C' doll's head fastener in 1862. Ultimate accuracy of fit must be achieved for the gun to feel smooth over the many thousands of times it will be opened and closed. The fastener is locked in placed by the equally distinctice sliding top bolt and wide pivoting lever, unique to the firm for over 100 years.

Touring the purpose-designed work spaces in the factory, seeing the craftsmen at their benches, intent but un-hurried as they attend to polishing, jointing or chequering, any visitor can see that Westley Richards guns and rifles have to be mechanically perfect and aesthetically beautiful in every respect. Everyone on-site is a perfectionist.

All lockwork is meticulously fitted by hand and regulated by the instinctive touch of the gunmaker, a skill developed over many years of patient practice.

All lockwork is meticulously fitted by hand and regulated by the instinctive touch of the gunmaker, a skill developed over many years of patient practice. The stocking is carried out by hand in the traditional manner, utilising the accuracy of a mere layer of smoke black. Individual pieces of only the finest seasoned walnut are selected, taking into consideration both strength of grain and beauty of figure. Every stock is a truly distinctive feature of the modern Westley Richards sporting gun and rifle.

The stocking is carried out by hand in the traditional manner, utilising the accuracy of a mere layer of smoke black. Individual pieces of only the finest seasoned walnut are selected, taking into consideration both strength of grain and beauty of figure. Every stock is a truly distinctive feature of the modern Westley Richards sporting gun and rifle.Plato once asserted that ‘nothing useless can be truly beautiful’. This philosophy is reflected in every aspect of gun-making here. Every facet of each product is shaped, linked and fitted so as to be the ideal of whatever it represents. Form and function are complimentary. The guns not only look beautiful, but that visual beauty is reinforced by the tactile beauty of mechanical efficiency. This combination ensures that beauty is not only seen by the user, but felt and experienced.

The transition from pure mechanical accuracy to artistic elegance is achieved with the final touches of the file. The lines and shapes, the rounded fences and angled valleys reflect the seasoned eye of the master gun-maker, rather than the cold precision of the computer or the machine. No two products are quite the same; each is an individual and has that innate artistry that only bench-work really creates. Sometimes visual perfection is achieved by eye, and it often differs form mathematical perfection. This is why sculptures carved by the hands of an artist appear to have 'life', while, technically flawless, machine-made equivalents don't.

Every commission is discussed with the customer before the engraver sets about his work. This will transform an elegantly functional gun or rifle into a very special, uniquely personal finished piece, one which will be a pleasure to hold, behold and take afield for generations to come.

Many Westley Richards guns and rifles made in 1900 are still in regular use. By adhering to the traditions that make their products world class, We expect those leaving the factory today will be approaching their prime when the customer’s grandchildren are ready to take them hunting.

There is no short-cut to quality. Each Westley Richards gun or rifle requires between 450 and 600 man-hours to deliver. To develop the skills to be one of those men takes years. The accumulation of talent, experience and care that goes into building a best gun here is, perhaps, unlike that required to create any other modern product. Perhaps only a hand-built racing car comes close to the art of gun-making in the way the passions and skills the team put into construction become tangible in the performance of the machinery in motion. It is a special place and these are special products.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.