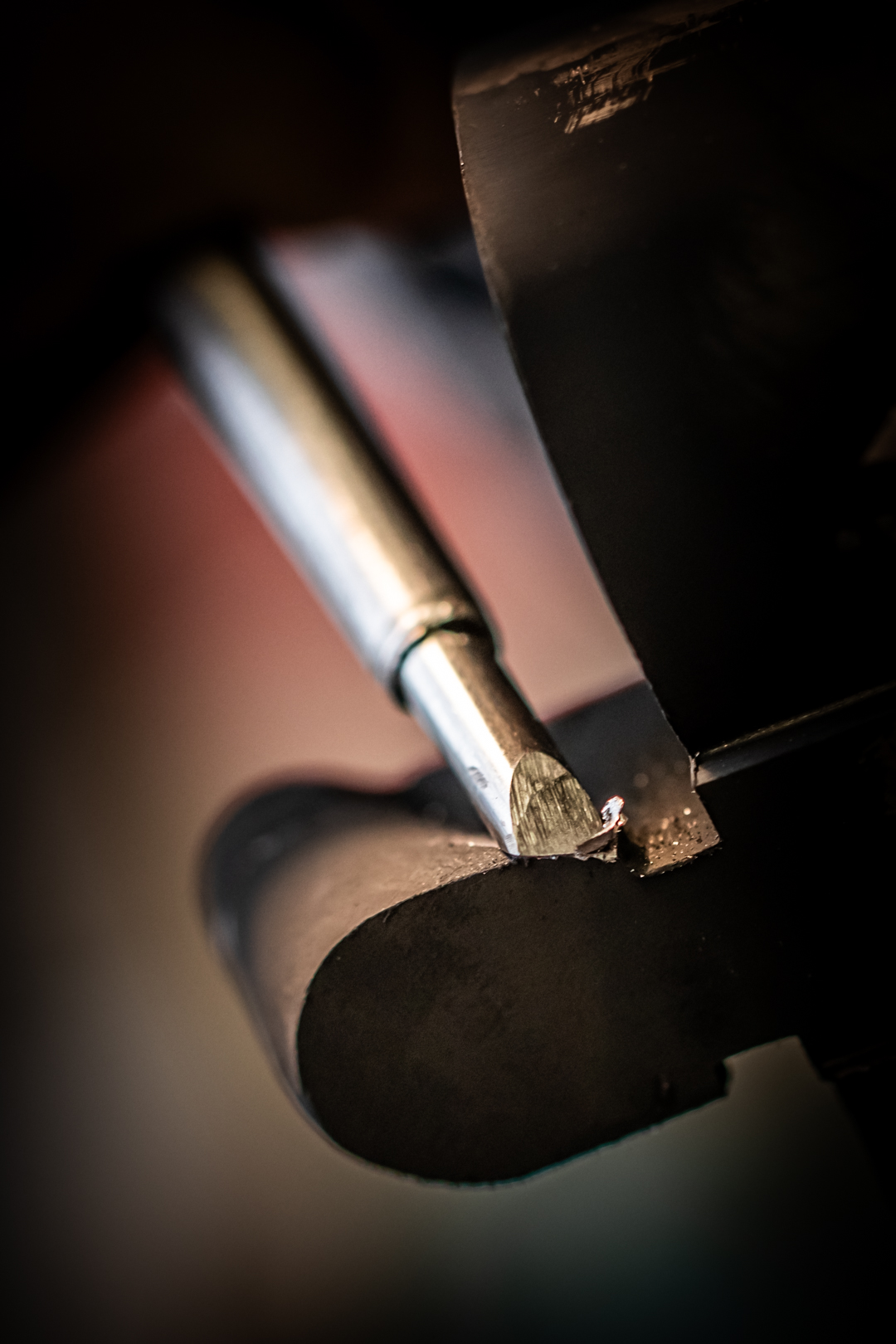

One of the most basic tools is the steel chisel used to cut shapes and furrows into the action. These come in various sizes and are hand-made in our factory by the gunmakers.

The largest is simply a length of steel bar, cut and turned, then tipped with a recess sized to receive a HSS steel tip, which is ground to a sharp edge and fixed in by adhesive. This is used very much in the manner of a stone mason’s chisel. It is struck with a hammer and used to shape the steel of the action, particularly the fences and beads.

With practice, a remarkable degree of precision can be achieved and shapes quickly formed that would take an age, if attempted with a file.

Another chisel commonly used is just referred to by foreman Stuart Richards as a ’small chisel’ and this is a sharpened length of hardened steel, honed into a chisel head at one end and used for cutting sight ‘V’s or channels for the the extractor leg cams etc.

The smallest chisel is actually made from a file, which is ground-down to shape on a wheel and sharpened at one end. This is used for cutting small slots in the action, behind the strikers.

These chisels are rudimentary-looking, basic objects, with no apparent finesse but they are a crucial part of a gun-maker’s toolbox. They save time, deliver precise cuts where they are needed, and do a specialized job very well.

The steels used to make the chisels; tool steel from a file, steel hardened in-house and HSS type steel are all much harder than the EN32 and EN34 steels generally used for actioning. As such, they cut cleanly and easily, when guided by skilled hands.

Once made, these tools can last for a decade, being regularly re-sharpened by hand on a grinding wheel.

It is typical of the gun trade that gunmakers create their own specialized tools for performing many very particular tasks that are unique to the industry.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.