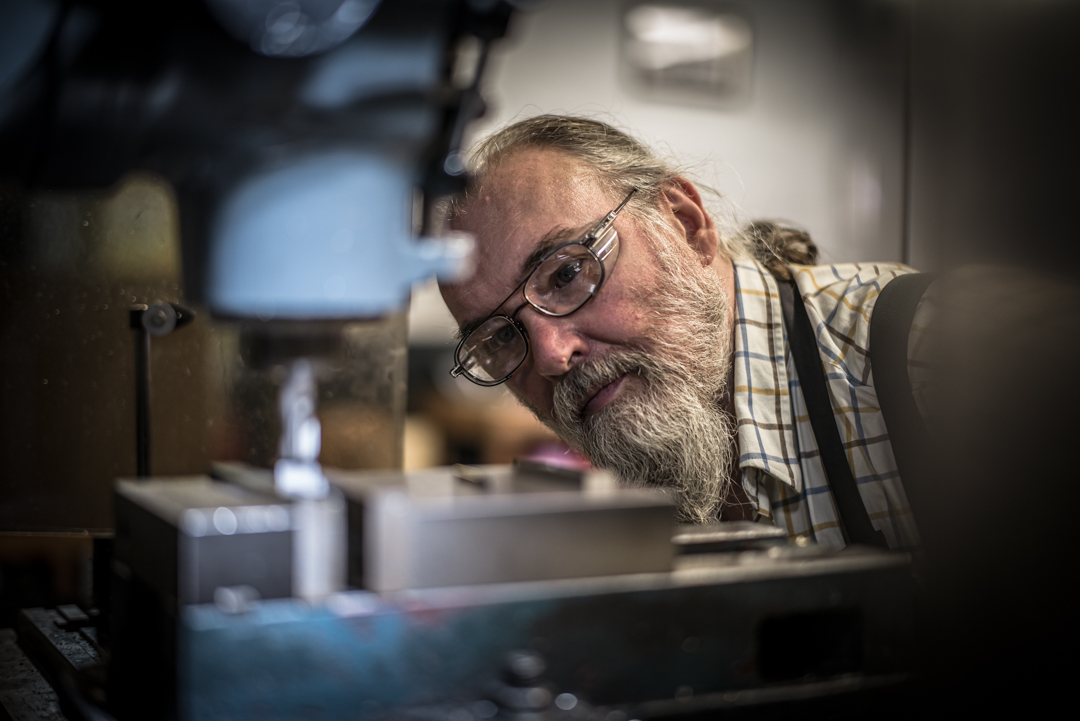

Peter is one of those who made that change, joining in his mid-fifties, after a sliding doors moment and a rekindling of his early years adoration for heritage firearms. He recently completed his apprenticeship with the company, receiving his signed and framed certificate from Trigger, ideal timing for him to share his story in one of our regular Westley Richards interviews.

Tell us about your background and where you grew up?

I was born in 1962 when everything was black and white, in Coseley, near Dudley. So Black country born and bred, strong in the arm and thick in the head.

My parents were quite old when I came along, Dad was 49 and Mum was 42 so I was bought up by people who were most other’s grandparents age, with their morals and way of thinking, which in my mind gave me a very strong foothold in life to come. Dad was born in South Africa whilst my grandfather served in the British army there, during the second Boer War. Mum was born in Berlin, Germany. They saw the worst of war from both sides between them and this drove their unease of anything firearms, very understandable.

The seeds were sown when I came home from school and instead of picking up my weekly copy of the Beano from the newsagents, I came back with a copy of Guns Review, on the cover was a cased pair of flintlock pistols and I was fascinated.

I grew up with a keen interest in art as a child and did a lot of sketches and oil painting. This led on to my curiosity with all things mechanical, the workings of a steam engine for example, and henceforth my obsession with taking everything apart to see how things work.

Dad swiftly bought me some Lego so that I could learn how to put things back together again. This taught me how to read and use drawings and how to assemble with instructions. An engineer was born.

My brother who was 20 years older than me, bought me my first air pistol on my 11th birthday, much to my father's disapproval, but that did it for me. We had miles of canals near me where my mates and I could shoot all day, and nobody gave a second look at a bunch of kids walking down to the canal with air guns slung over your shoulders, try doing that today.

I joined the air cadets at 13, and by 14 I was shooting .303 Enfield rifles, quickly gaining my ATC then RAF Marksman patches. Learning about engines, airframes, propulsion and weapons drew me to a career with the RAF in my sights, going in as technician when I left school at 16, subject to the right exam results. I failed to get the right results in physics, which was my favourite subject and that was like a kick in the teeth for me. So, plan B was an engineering apprenticeship. Quite a few of my neighbours worked in a company called Thompson Tankers in Bilston, a well-established company with a good reputation for training, that made aircraft refuelers, road tankers and bulk food transporters.

Looking back, it was a great apprenticeship, we built the complete vehicle from bare metal to a finished product on site, so we had the engineering capacity and I trained in every department. I learned a vast amount covering 5 years training, then I went on at my own expense another 2 years advanced training in supervision and management. This laid the foundations for a successful engineering career in further employment with other companies, including working overseas in Africa and America.

Did you always want to be a gunmaker?

Motorcycles quickly dominated my everyday life and hobbies; restoration of vintage bikes and custom work focused my benchwork in my spare time. Family also took over. Firearms had taken a back seat for me at this time, and the stigma growing against anything firearms related, plus all the hoops you have to jump through to enjoy shooting as a pastime.

Then a long spell of 5 weeks being immobilised in my bed with back problems, a consequence of a car accident I was involved in, which disabled my wife, gave me time to re-evaluate where I was going and what I wanted to do. I watched a video about gunsmithing and gunmaking in colonial America, filmed in the sixties by a gunmaker and his apprentice making a flintlock rifle from scratch using only early 18th century methods. Wow, I really wanted to do this. Therefore I started the long process of getting my firearms certificate with the intention of building my own flintlock rifle eventually (shown in last image).

What did your apprenticeship entail?

My first apprenticeship was with Thompsons, first year basic engineering encompassing machine work, electrical engineering, fitting and fabrication, welding and brazing plus the theory, full time plus two nights a week. Then on to full time working with one day and two nights a week at college.

Finally, two years supervision and management studies which qualified me with a licenciate membership of the City & Guilds. This essentially qualified me to teach fabrication engineering if I chose to do so.

My training with Westley Richards was more product knowledge along with a refinement of rusty bench skills due to being mostly in a factory environment. The firearm knowledge I had was predominantly on historic military weapons than modern sporting guns and rifles, so the learning began.

My personal emphasis was to ease the load from the more skilled and knowledgeable gunmakers by doing the more mundane and basic tasks, thus giving them more time to focus on the more in depth levels of gunmaking. Over time those very jobs also came under my belt, so I think I progressed from being a help to the team to being one of the team.

How long have you been at Westley Richards?

I started in April 2018, so it will be six years soon.

Who inspired you to become a gunmaker?

I have a keen interest in historical firearms, especially flintlock rifles and muskets, as well as their development and evolution into what we know today. I have already mentioned an old video about American colonial gunsmiths, and the apprentice in that film inspired me.

A gent by the name of William Gusler also inspired me. He was still alive and kicking last time I looked and still making guns well into his 80s I believe. He not only forged all the steel and brass but made every last pin and screw, plus the tools he worked with from crucible steel. Amazing to watch. Everything he did, I have done but not in a gunmaking scenario.

Who would you count as mentors in the field of actioning?

Three main people, Sam Banner, Stuart Richards and James Grinyer. Each one of them has valuable skills and knowledge across a broad range, not just in Westley’s. Sam was a real driver for quality and doing things to the book, very skilled and knowledgeable. And between Stuart, our foreman, and James, there is nothing that can't be done, two very skilled gunmakers.

How long did it take to learn the art of building an action?

I have a varied role in the actioning, a lot of my time is taken up at the extreme ends of building a gun. Firstly with the sub-assemblies, sights, ejector boxes, trigger assemblies, convergence etc, then finishing the final piece where all the jewelling finish and final polish takes place. So, a difficult question to answer really, you could say you don't stop learning. You have to integrate customers’ bespoke requests with Westley Richards tradition and then Trigger gets involved!!! It doesn't take long to learn the basics but then you add the weird and wonderful.

How many actions have you now built?

Again a difficult one to answer. I have been hands on with most of the double rifles and shotguns that have been built in the last 4 years at least, which I’m told is upwards of eighty.

What are the greatest challenges an actioner faces?

There will always be problems of one sort or another, which sneak up on you with any handcrafted item. I suppose distortion after colour case hardening can be frustrating. After everything has been freed up initially, it can need repeating to some degree. Mainly keep an eye on customers specifications and don't take anything for granted.

What do you most enjoy about building an action?

I do enjoy the trigger assemblies, the file up of the trigger bows and triggers, something very satisfying about that.

Tell us about a patron’s project that you were proud of recently, and why?

Although I am very proud of all the jobs I have worked on, there was a quartet of shotguns a while back, all different calibres but all for the same customer. From 410 to 12 bore. These were my first guns which I had a lot of input in, all had to look like a set. A good feeling to know you had a part in all of them.

The Explora Blog is the world’s premier online journal for field sports enthusiasts, outdoor adventurers, conservationists and admirers of bespoke gunmaking, fine leather goods and timeless safari clothes. Each month Westley Richards publishes up to 8 blog posts on a range of topics with an avid readership totalling 500,000+ page views per year.

Blog post topics include: Finished custom rifles and bespoke guns leaving the Westley Richards factory; examples of heritage firearms with unique designs and celebrated owners like James Sutherland and Frederick Courtenay Selous; the latest from the company pre-owned guns and rifles collection; interviews with the makers from the gun and leather factory; new season safari wear and country clothing; recent additions to our luxury travel bags and sporting leather goodsrange; time well spent out in the field; latest news in the sporting world; and key international conservation stories.

neil mcveigh on February 29, 2024 at 5:32 am

Inspiring story Peter.Clearly a great addition to the team at WR.Look forward to seeing more of the teams wonderful products in these pages, it certainly makes me smile.