The original purpose of spotting was to create micro-abrasions on the surface of the steel, which would make it hold oil better, thereby increasing the protection afforded against corrosion.

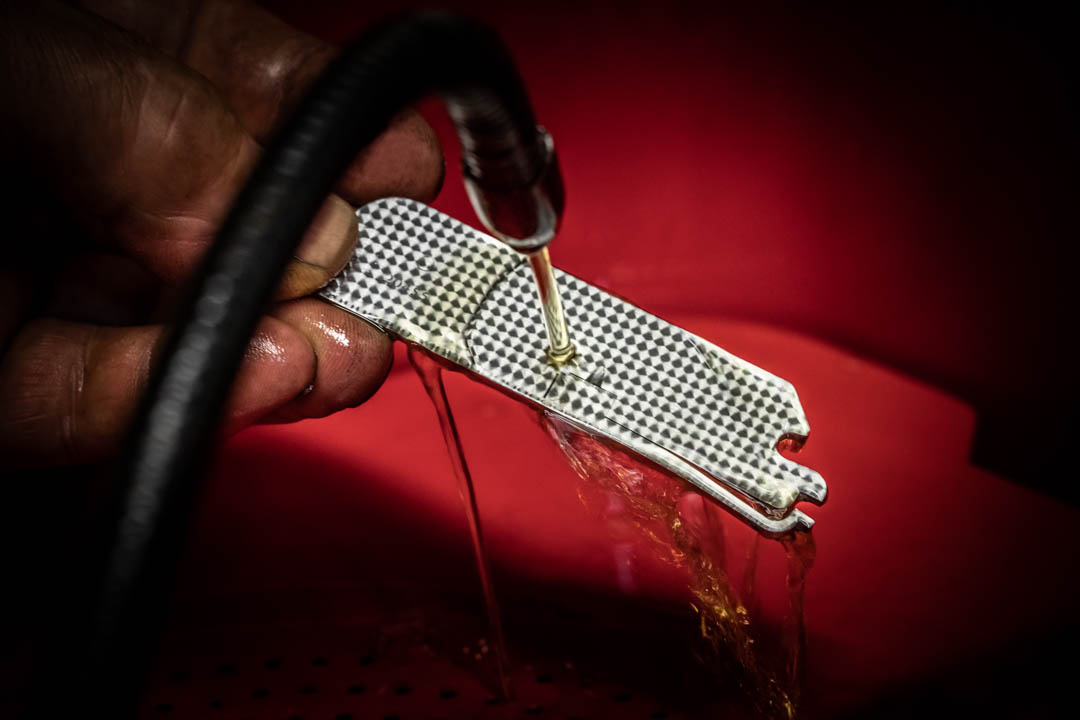

It is achieved by applying fine abrasive paste to a hard rubber tip on the end of a spindle machined to the desired size. This is placed in a fixed-position drill which is lowered onto the steel and held lightly in place long enough to produce a disc-shaped abrasion. The piece being spotted is then moved along two millimetres and the next spot applied.

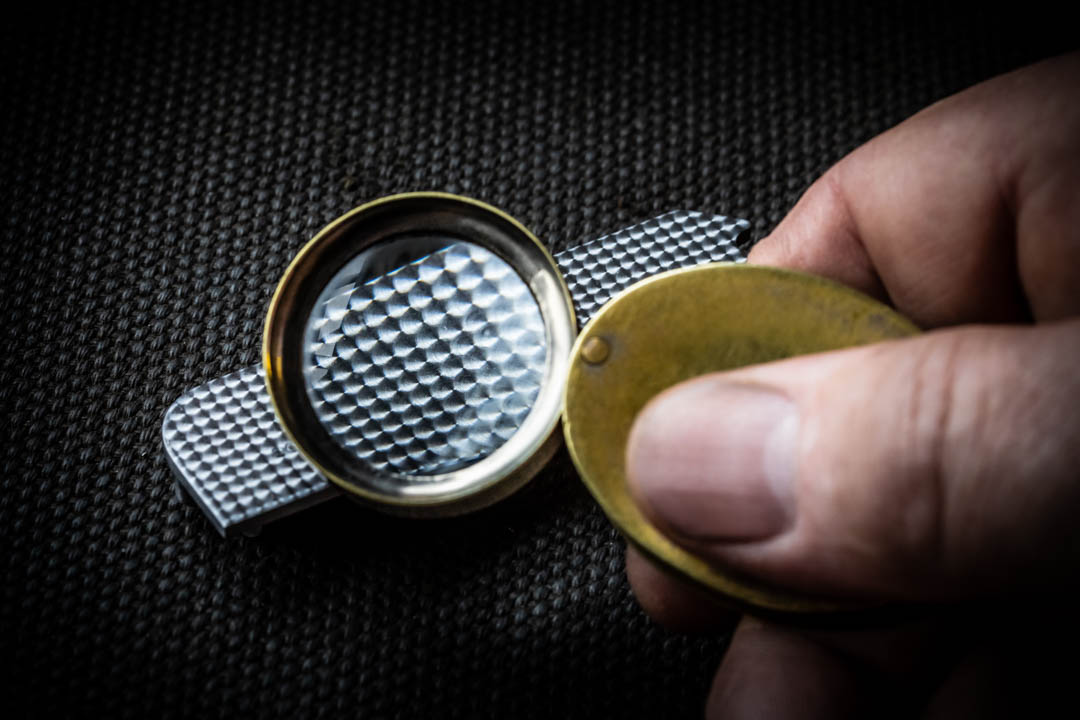

This process is repeated until the entire surface is covered with slightly over-lapping circles, which reflect light in different directions and give the impression that the surface is covered with glittering jewels.

We commonly apply spotting to the inner surfaces of magazine rifles, the inside of the floor plate and to the bolt-shaft.

For the Deeley-patent, hand-detachable locks in our double rifles and shotguns, we spot every limb of the lock-work and its mounting plate, as well as the inner surface of the floor plate.

With modern steels and lubricants, the practical benefits of spotting are debatable, but it certainly adds a degree of finesse to what would otherwise be expanses of unadorned steel.

For one gunmaker to spot the bolt and floor plate of a magazine rifle takes five hours, to do a set of locks on a double gun or rifle we allow eight-and-a-half hours.

It is a time-consuming, fiddly job but that finesse it adds to our rifles and guns makes it worthwhile. In every major build it is details like this that combine to deliver the ultimate beauty of the finished product.

Whether for the discerning collector or the avid sportsman, Westley Richards firearms represent the epitome of excellence in the world of bespoke gunmaking. Known for the droplock shotgun, over and under shotgun, double barrel rifle and bolt action rifle, the company has achieved an illustrious 200 year history of innovation, craftmanship and artistry. As part of our best gun build, clients can choose from three levels of gun engraving: the house scroll; signature game scenes; and exhibition grade masterpieces. All Westley Richards sporting arms are built at their factory in Birmingham, England. Discover more about the gunmaking journey at our custom rifles and bespoke guns pages.