Certainly, other hammerless designs pre-date the Anson & Deeley but none are now in production, indeed few of them were still in production by 1880.

One of the key obsessions with sportsmen and gunmakers in the great period of invention which led us from muzzle-loaders to modern centre-fire, break action breech-loaders, was safety.

This is entirely understandable. Sportsmen used to a gun with a solid breech plug between them and the explosion used to propel their charge down range suddenly had to accept a gun that actually broke in half an inch from their nose! This is the reason for so many complex (sometimes overly-complex) multiple-bolt locking mechanisms being patented in the mid-Victorian era.

Another issue for hammerless guns was the fact that the hammers could not be seen as cocked or at rest. When closed they were automatically cocked and therefore potentially dangerous. Safety systems began to get incorporated into hammerless designs, intended to guard against unintentional discharge.

One approach involved blocking the triggers, so they could not be pulled by accident. Early versions include the grip safety, found on some hammer guns. Modern hammerless guns tend to have a trigger-locking safety mechanism operated by a top-slide mounted on the guard strap. Greener famously preferred his on the side of the stock; his ‘side safety’ button.

In 1879 the patentees of the original design for the boxlock, William Anson and John Deeley (Senior), submitted a new invention to incorporate an intercepting safety mechanism into the gun they had devised four years earlier.

The patent was granted on 26th August 1879 and given Patent No. 907, dated 7th March 1879. It covers several improvements, all in the manner of intercepting safety mechanisms. Two are intercepting sears, one is a blocking device.

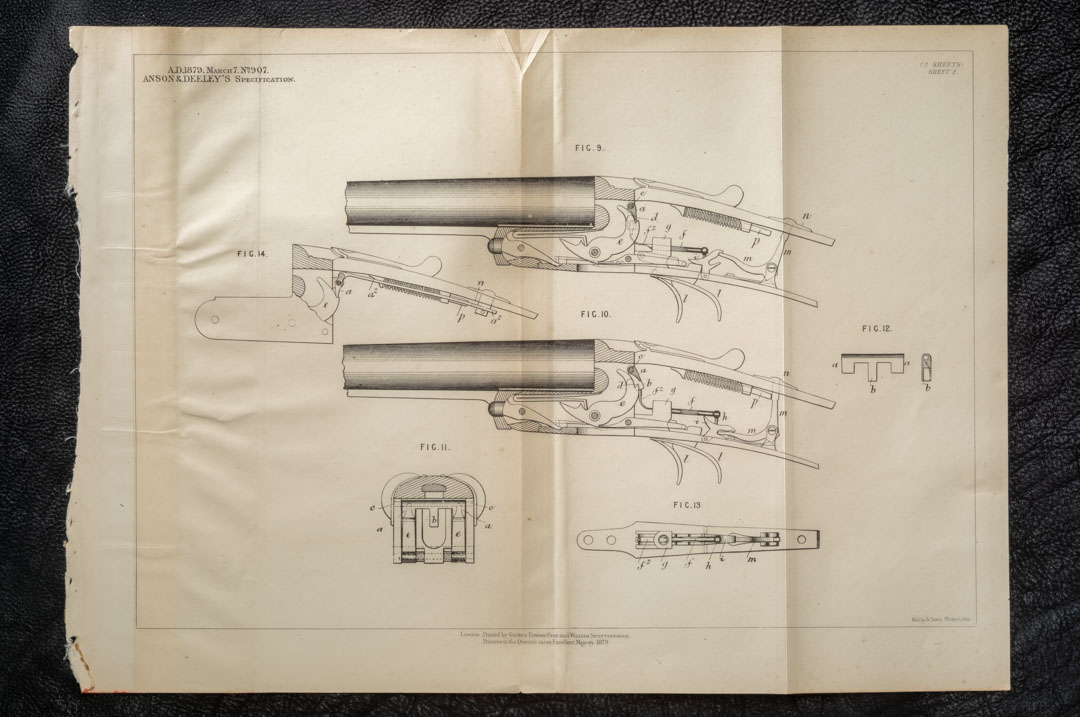

The intercepting sears prevent the fall of the hammer by holding in a notch on its back surface. They can be operated solely by a top-slide safety catch or in tandem with a secondary mechanism preventing the fall of the hammer without the trigger being pulled.

The blocking device is placed between the hammer and the breech, preventing the former from reaching the latter and delivering its blow to the cap.

This patent blocking device is exemplified in a rare 12-bore boxlock gun in the Westley Richards collection; serial number 12948.

Externally, the obvious indicators are the twin safety catches, one either side of the action body. These operate independently and protect their respective locks.

The blocking device itself is a simple bar, split in the middle to allow for independent movement either side, so one lock can be placed on safe and the other not.

The bar extends horizontally through the action, behind the fences and below the striker holes. ’That portion of the axis (bar) situated in front of the hammer is partly cut-away so that when the said axis is in such a position that the un-cut-away portion is uppermost the hammer cannot fall sufficiently far to discharge the gun’. This is how Anson & Deeley describe the position of the block when in ‘safe’ mode.

To render the gun ready to shoot they continue; ‘ when the axis has been turned through a sufficient angle to bring the cutaway part uppermost, the hammer is not obstructed by the said axis and the gun can be discharged’.

In order to re-set the gun to ‘safe, once it has been manually set to ‘live’, it must be opened and closed. A rod, activated by the lump (early Westley Richards breech-loaders have only one lump) slides through the action and bears on the horizontal axis to re-set it to ‘Safe’ when the gun is opened and closed. There is one rod (which is a flattened oblong in section) for each side.

This system is rarely encountered in production guns. We know only of two by Westley Richards and one by Newton.

The example we have, No.12948, was (according to our registers) made in December 1876 and was ‘on consignment with Welch & Scott’ that year. Further notes show that in August 1878 it was sold to ‘A. Taylor’ and that is was back with the company in December 1930. This is interesting, as it suggests that the gun was made prior to the filing of the patent for the interceptor, just a few months after the patent for the Anson & Deeley action itself.

Could it be the first of its kind? Perhaps a prototype? We cannot know for sure but it seems likely.

The gun remains in remarkable condition. Almost all the original finish is in tact on the metal parts. The drop points and chequer look original and un-worn. Mechanically, it is perfect, opening and snapping closed on its Westley Richards patent bolted top-lever alone, without the Purdey double under-bolt that was added to later models.

It is, of course, a non-ejector and appears to conform to the patent specifications for No.907, although the rods re-setting the interceptor upon opening and closing the gun act off a sliding limb on the forend iron, rather than directly off the lump, as described in the patent’s wording.

The engraving is fine, best scroll and the safety catches appear to have been gold-washed originally, though traces of this remain only on the right hand side. It has the number 30 stamped on the bar flats and the forend iron.

The forend is attached by another Westley Richards idea; the Deeley & Edge catch; Patent No.1422 of 1873.

With 30” Damascus barrels and a 14 ½” straight hand stock of dark, straight grained walnut, it is eminently shootable. One can only wonder how it survived for one hundred and forty six years and saw so little action.

The Explora Blog is the world’s premier online journal for field sports enthusiasts, outdoor adventurers, conservationists and admirers of bespoke gunmaking, fine leather goods and timeless safari clothes. Each month Westley Richards publishes up to 8 blog posts on a range of topics with an avid readership totalling 500,000+ page views per year.

Blog post topics include: Finished custom rifles and bespoke guns leaving the Westley Richards factory; examples of heritage firearms with unique designs and celebrated owners like James Sutherland and Frederick Courtenay Selous; the latest from the company pre-owned guns and rifles collection; interviews with the makers from the gun and leather factory; new season safari wear and country clothing; recent additions to our luxury travel bags and sporting leather goodsrange; time well spent out in the field; latest news in the sporting world; and key international conservation stories.